Proper management of the product base is made up of a number of processes, such as:

- allocating a SKU (stock keeping unit) number to each product, variant or bundle and labelling it accordingly,

- collecting data on all products. Every change – e.g. a new supply of a product variant, a reduction in stock after a sale – must be recorded in the system. It is important that creating logs is simple and intuitive.

- Analysis of data concerning the entire base – as a retailer you should know what products and in what quantity are actually on the shelves in the warehouse. The system must properly reflect reality.

- generating the relevant warehouse documents.

In summary – as an entrepreneur you need to have a full picture of what is happening in your warehouse – in real time. BaseLinker’s Product Manager will make this task easier for you.

The Inventory Control module contains a number of useful options:

- keeps an eye on the uniqueness of product SKUs,

- allows the processing of warehouse documents – thanks to this any change, e.g. a new batch is accepted into the warehouse, a new product is released – will be recorded in the system,

- introduces blockade of manual stock change – stock is changed only via the synchronisation module or by entering a new delivery,

Please note that this module should only be enabled in the last step of the Product Manager configuration.

Control

In the Products → Inventory Control section, there are eight tabs that will allow you to perform basic warehouse control processes more efficiently:

- Purchase orders – this component of the system will allow you to:

- ordering products from suppliers – here you define what products will be included in your order – in what quantity, with what code, at what price, from which supplier, with what additional costs. You can track the progress of a given delivery. After its completion, the system will automatically issue a PZ document,

- manage different orders – as your e-commerce grows you will be placing more and more orders to an increasing number of suppliers. BaseLinker allows you to monitor when a particular delivery will arrive, to which warehouse, whether the delivery matches what was sent in the order, etc.,

- increase the stock of the products as delivered;

- Storage documents – this section records all transfers within the warehouse;

- Stocktakes – the module will allow you to check whether the stocks are consistent;

- Fulfillment deliveries;

- Warehouse’s value – here, every day around midnight, a summary of all products in the BaseLinker warehouse is generated, along with the total stock level and its value;

- Numbering series – section contains the configuration of different types of warehouse documents;

- Printout templates – here you can create and modify print templates for deliveries and stocktakes;

- Document register – in this tab, you can filter and download all issued documents according to selected guidelines.

Product card

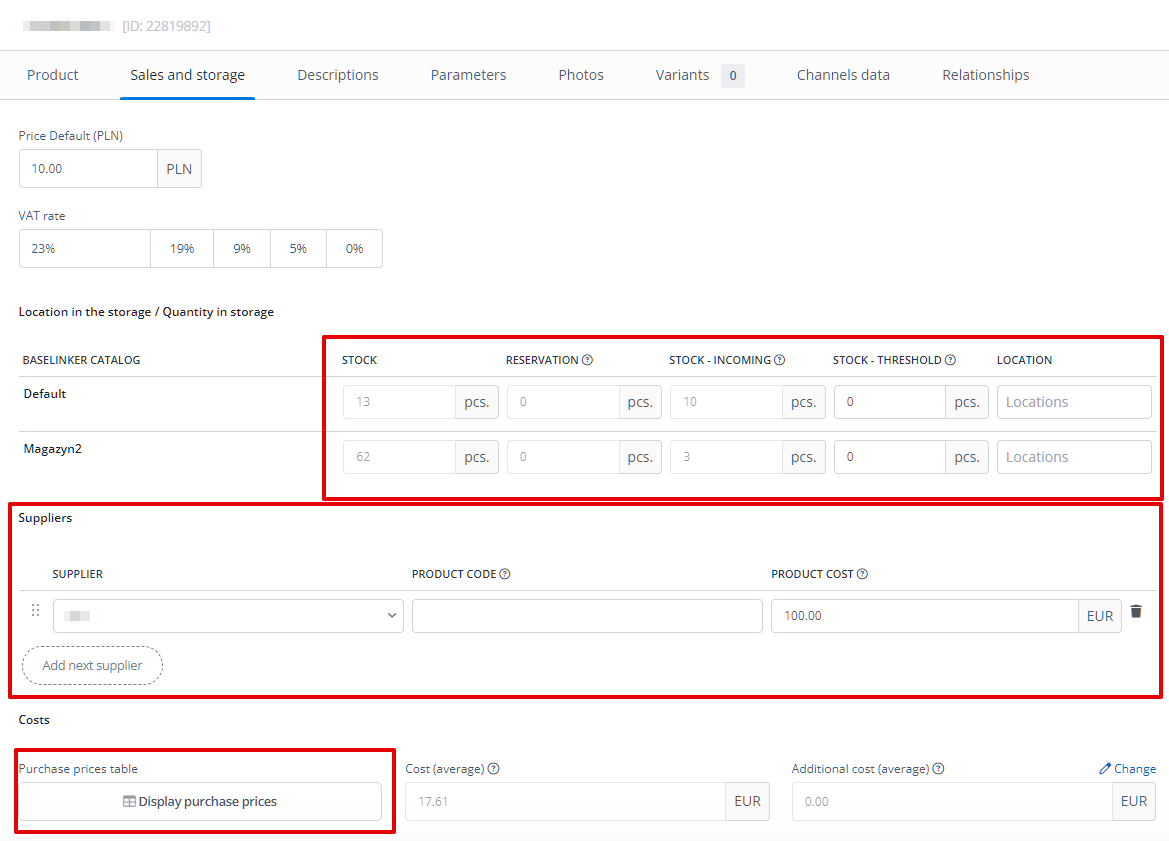

On the product card, in the Sales and warehouse section, you will find information about which supplier the product comes from and at what price it was purchased.

In the case of purchase price accounting using the standard AVCO method, in the Sales and warehouse tab on the product card, you will see the average purchase price and average additional cost calculated based on the prices entered in deliveries.

However, if you have chosen one of the FIFO, LIFO, FEFO, or LEFO algorithms, a Purchase price table will be available, where you can check the list of all deliveries containing this product along with their receipt date, warehouse document number, quantity, and purchase price.

Please note that the same product may come from several suppliers.